Abstract

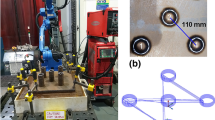

A new modification of constrained groove pressing (CGP) process named as constrained groove pressing–cross route (CGP-CR) was suggested for severe plastic deformation (SPD) of sheet form metals with great potential for fabricating high strength nanostructured sheets. This process is based on the conventional CGP process including some modifications. One pass of this process includes eight stages (four corrugation and four flattening) and involves 90° cross-rotation between each two stages. As a result of each CGP-CR pass, a strain magnitude of ∼2.32 is imparted to the sample. To simulate the process, finite element modeling (FEM) was carried out using three-dimensional finite element analysis ABAQUS/Explicit simulation. Strain and hardness distribution through the sheet after CGP-CR process at different stages were examined via FEM. Low-carbon steel sheet was utilized as the testing material and CGP-CR process imparted upon it up to two passes. Afterward, equivalent plastic strain was measured ∼4.64. Results show that the magnitude and uniformity of strain were different along three main directions of sheets: rolling (RD), transverse (TD), and normal directions (ND), at different stages of process. In addition, the results indicate that, for the CGP-CR’d sheets up to two passes, the magnitude and uniformity of hardness simulated via FEM were consistent with the experimental data.

Similar content being viewed by others

References

Vinogradov A (2007) Fatigue limit and crack growth in ultra-fine grain metals produced by severe plastic deformation. J Mater Sci 42:1797–1808. doi:10.1007/s10853-006-0973-z

Vinogradov A, Patlan V, Suzuki Y, Kitagawa K, Kopylov VI (2002) Structure and properties of ultra-fine grain Cu–Cr–Zr alloy produced by equal-channel angular pressing. Acta Mater 50:1639–1651. doi:10.1016/S1359-6454(01)00437-2

Sergueeva AV, Stolyarov VV, Valiev RZ, Mukherjee AK (2000) Enhanced superplasticity in a Ti–6Al–4V alloy processed by severe plastic deformation. Scr Mater 43:819–824. doi:10.1016/S1359-6462(00)00496-6

Neishi K, Uchida T, Yamauchi A, Nakamura K, Horita Z, Langdon TG (2001) Low-temperature superplasticity in a Cu–Zn–Sn alloy processed by severe plastic deformation. Mater Sci Eng, A 307:23–28. doi:10.1016/S0921-5093(00)01970-5

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Bulk nanostructured materials from severe plastic deformation. Prog Mater Sci 45:103–189. doi:10.1016/S0079-6425(99)00007-9

Suryanarayana C (2001) Mechanical alloying and milling. Prog Mater Sci 46:1–184. doi:10.1016/S0079-6425(99)00010-9

Gordon WO, Morris JR, Tissue BM (2009) Control of morphology in inert-gas condensation of metal oxide nanoparticles. J Mater Sci 44:4286–4295. doi:10.1007/s10853-009-3636-z

Francis SA, Tucker RT, Brett MJ, Bergens SH (2013) Structural and activity comparison of self-limiting versus traditional Pt electro-depositions on nanopillar Ni films. J Power Sources 222:533–541. doi:10.1016/j.jpowsour.2012.09.025

Hashempour M, Vicenzo A, Zhao F, Bestetti M (2013) Direct growth of MWCNTs on 316 stainless steel by chemical vapor deposition: effect of surface nano-features on CNT growth and structure. Carbon 63:330–347. doi:10.1016/j.carbon.2013.06.087

Singh J, Wolfe DE (2005) Nano and macro-structured component fabrication by electron beam-physical vapor deposition (EB-PVD). J Mater Sci 40:1–26. doi:10.1007/s10853-005-5682-5

Estrin Y, Vinogradov A (2013) Extreme grain refinement by severe plastic deformation: a wealth of challenging science. Acta Mater 61:782–817. doi:10.1016/j.actamat.2012.10.038

Li L, Virta J (2011) Ultrahigh strength steel wires processed by severe plastic deformation for ultrafine grained microstructure. Mater Sci Technol 27:845–862. doi:10.1179/026708310X12677993662087

Prasad RVS, Phanikumar G (2009) Amorphous and nano crystalline phase formation in Ni2MnGa ferromagnetic shape memory alloy synthesized by melt spinning. J Mater Sci 44:2553–2559. doi:10.1007/s10853-009-3333-y

Sakai T, Belyakov A, Kaibyshev R, Miura H, Jonas JJ (2014) Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog Mater Sci 60:130–207. doi:10.1016/j.pmatsci.2013.09.002

Liu J, Zhang L, Song L, Meng L, Zeng Y, Wang M et al (2014) Dislocation assisted face-centered-cubic/body-centered-cubic interface mixing during severe plastic deformation. J Alloys Compd 586:16–21. doi:10.1016/j.jallcom.2013.09.061

Singh JB, Kapoor R, Durga Prasad A, Chakravartty JK (2013) Comparison of microstructures and strengths of an Al–2.5 Mg alloy subjected to severe plastic deformation at room and liquid nitrogen temperatures. Mater Sci Eng, A 581:26–30. doi:10.1016/j.msea.2013.05.073

Beyerlein IJ, Tóth LS (2009) Texture evolution in equal-channel angular extrusion. Prog Mater Sci 54:427–510. doi:10.1016/j.pmatsci.2009.01.001

Adamczyk-Cieślak B, Mizera J, Kurzydłowski KJ (2011) Microstructures in the 6060 aluminium alloy after various severe plastic deformation treatments. Mater Charact 62:327–332. doi:10.1016/j.matchar.2011.01.009

Valiev RZ, Langdon TG (2006) Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog Mater Sci 51:881–981. doi:10.1016/j.pmatsci.2006.02.003

Zhilyaev AP, Langdon TG (2008) Using high-pressure torsion for metal processing: fundamentals and applications. Prog Mater Sci 53:893–979. doi:10.1016/j.pmatsci.2008.03.002

Latypov MI, Alexandrov IV, Beygelzimer YE, Lee S, Kim HS (2012) Finite element analysis of plastic deformation in twist extrusion. Comput Mater Sci 60:194–200. doi:10.1016/j.commatsci.2012.03.035

Richert M, Liu Q, Hansen N (1999) Microstructural evolution over a large strain range in aluminium deformed by cyclic-extrusion-compression. Mater Sci Eng, A 260:275–283. doi:10.1016/S0921-5093(98)00988-5

Tsuji N, Saito Y, Lee SH, Minamino Y (2003) ARB (accumulative roll-bonding) and other new techniques to produce bulk ultrafine grained materials. Adv Eng Mater 5:338–344. doi:10.1002/adem.200310077

Shin DH, Park JJ, Kim YS, Park KT (2002) Constrained groove pressing and its application to grain refinement of aluminum. Mater Sci Eng, A 328:98–103. doi:10.1016/S0921-5093(01)01665-3

Lee JW, Park JJ (2002) Numerical and experimental investigations of constrained groove pressing and rolling for grain refinement. J Mater Process Technol 130–131:208–213. doi:10.1016/S0924-0136(02)00722-7

Huang JY, Zhu YT, Jiang H, Lowe TC (2001) Microstructures and dislocation configurations in nanostructured Cu processed by repetitive corrugation and straightening. Acta Mater 49:1497–1505. doi:10.1016/S1359-6454(01)00069-6

Zrnik J, Kovarik T, Novy Z, Cieslar M (2009) Ultrafine-grained structure development and deformation behavior of aluminium processed by constrained groove pressing. Mater Sci Eng, A 503:126–129. doi:10.1016/j.msea.2008.03.050

Krishnaiah A, Chakkingal U, Venugopal P (2005) Production of ultrafine grain sizes in aluminium sheets by severe plastic deformation using the technique of groove pressing. Scr Mater 52:1229–1233. doi:10.1016/j.scriptamat.2005.03.001

Khakbaz F, Kazeminezhad M (2012) Work hardening and mechanical properties of severely deformed AA3003 by constrained groove pressing. J Manuf Processes 14:20–25. doi:10.1016/j.jmapro.2011.07.001

Khakbaz F, Kazeminezhad M (2012) Strain rate sensitivity and fracture behavior of severely deformed Al–Mn alloy sheets. Mater Sci Eng, A 532:26–30. doi:10.1016/j.msea.2011.10.057

Krishnaiah A, Chakkingal U, Venugopal P (2005) Applicability of the groove pressing technique for grain refinement in commercial purity copper. Mater Sci Eng, A 410–411:337–340. doi:10.1016/j.msea.2005.08.101

Peng K, Zhang Y, Shaw LL, Qian KW (2009) Microstructure dependence of a Cu–38Zn alloy on processing conditions of constrained groove pressing. Acta Mater 57:5543–5553. doi:10.1016/j.actamat.2009.07.049

Satheesh Kumar SS, Raghu T (2013) Mechanical behaviour and microstructural evolution of constrained groove pressed nickel sheets. J Mater Process Technol 214:213–220. doi:10.1016/j.jmatprotec.2012.09.012

Sunil BR, Kumar AA, Sampath Kumar TS, Chakkingal U (2013) Role of biomineralization on the degradation of fine grained AZ31 magnesium alloy processed by groove pressing. Mater Sci Eng, C 33:1607–1615. doi:10.1016/j.msec.2012.12.095

Khodabakhshi F, Kazeminezhad M, Kokabi AH (2010) Constrained groove pressing of low carbon steel: nano-structure and mechanical properties. Mater Sci Eng, A 527:4043–4049. doi:10.1016/j.msea.2010.03.005

Khodabakhshi F, Kazeminezhad M (2011) The effect of constrained groove pressing on grain size, dislocation density and electrical resistivity of low carbon steel. Mater Des 32:3280–3286. doi:10.1016/j.matdes.2011.02.032

Ramakrishnan N, Arunachalam VS (1997) Finite element methods for materials modelling. Prog Mater Sci 42:253–261. doi:10.1016/S0079-6425(97)00031-5

Liu C-H (2007) The simulation of the multi-pass and die-less spinning process. J Mater Process Technol 192–193:518–524. doi:10.1016/j.jmatprotec.2007.04.021

Estrin Y, Tóth LS, Molinari A, Bréchet Y (1998) A dislocation-based model for all hardening stages in large strain deformation. Acta Mater 46:5509–5522. doi:10.1016/S1359-6454(98)00196-7

Khodabakhshi F, Abbaszadeh M, Eskandari H, Mohebpour SR (2013) Application of CGP-cross route process for microstructure refinement and mechanical properties improvement in steel sheets. J Manuf Processes 15:533–541. doi:10.1016/j.jmapro.2013.08.001

Yoon SC, Krishnaiah A, Chakkingal U, Kim HS (2008) Severe plastic deformation and strain localization in groove pressing. Comput Mater Sci 43:641–645. doi:10.1016/j.commatsci.2008.01.007

Shirdel A, Khajeh A, Moshksar MM (2010) Experimental and finite element investigation of semi-constrained groove pressing process. Mater Des 31:946–950. doi:10.1016/j.matdes.2009.07.035

Tóth LS (2005) Modelling of strain hardening and microstructural evolution in equal channel angular extrusion. Comput Mater Sci 32:568–576. doi:10.1016/j.commatsci.2004.09.007

Peng K, Mou X, Zeng J, Shaw LL, Qian KW (2011) Equivalent strain, microstructure and hardness of H62 brass deformed by constrained groove pressing. Comput Mater Sci 50:1526–1532. doi:10.1016/j.commatsci.2010.12.010

Pandey SC, Joseph MA, Pradeep MS, Raghavendra K, Ranganath VR, Venkateswarlu K et al (2012) A theoretical and experimental evaluation of repetitive corrugation and straightening: application to Al–Cu and Al–Cu–Sc alloys. Mater Sci Eng, A 534:282–287. doi:10.1016/j.msea.2011.11.070

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khodabakhshi, F., Abbaszadeh, M., Mohebpour, S.R. et al. 3D finite element analysis and experimental validation of constrained groove pressing–cross route as an SPD process for sheet form metals. Int J Adv Manuf Technol 73, 1291–1305 (2014). https://doi.org/10.1007/s00170-014-5919-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5919-z